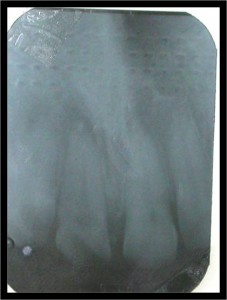

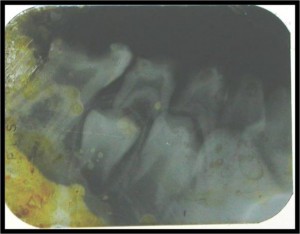

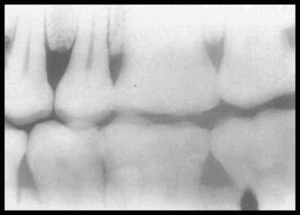

PROBLEM: HERRING BONE OR TIRE-TRACK IMAGE

CAUSE: Film placed backward and then exposed. X-ray beam attenuated

by the lead foil backing in the film packet

ACTION: Always place the white side of the film adjacent to the teeth

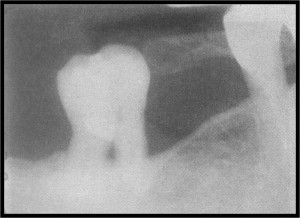

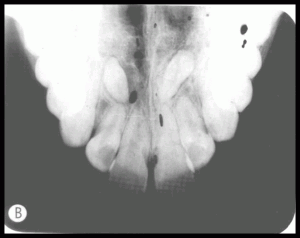

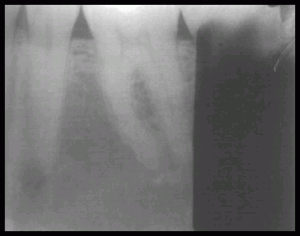

PROBLEM: PHALANGIOMA

CAUSE: Pt’s finger incorrectly placed in front of film instead of

behind the film. Pt’s finger appears on film.

ACTION: Avoid a phalangioma, make certain that the pt’s finger used to

stabilize the film is placed behind the film and not in front

Processing problems and solution

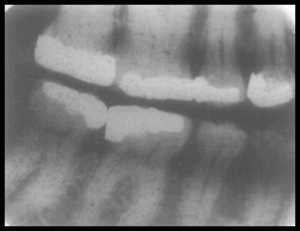

PROBLEM: LIGHT IMAGE

CAUSE: lack of mixing solutions to prevent stratification, temperature too low,

development time too short, inactive solutions (too old), depleted solution.

ACTION: Check thermostat,, development time, replace faulty thermometers and

replenishment frequency.

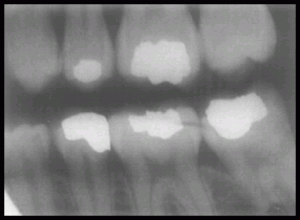

PROBLEM : DARK IMAGE

CAUSE : temperature too high, development too long,

Concentrated developer solution.

ACTION: Check thermostat, development time,

And replenishment frequency

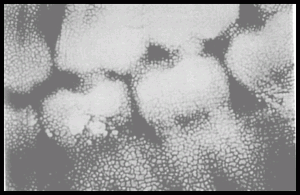

RETICULATION OF EMULSION

Cause: reticulation of emulsion results when a film is subjected

to a sudden temperature change between the developer

solution and the water bath

Action: check the temp of the processing solutions and water bath, avoid

drastic temperature differences between the developer and the water bath

PROBLEM : DARK SPOTS

CAUSE: Developer spots are seen when the developer solution

comes in contact with the film before processing

ACTION: Use a clean working surface in the darkroom, place

a paper towel on the work area before unwrapping films

PROBLEM : WHITE SPOTS

CAUSE: Fixer solution coming in contact with the film

before processing

ACTION: use clean working area in dark room, place a

Paper towel on work area before unwrapping.

PROBLEM : BROWN IMAGE

CAUSE: Oxidized developer, old developer, insufficient fixation

and insufficient rinsing

ACTION : Replenish or replace chemicals, check processing

procedure, use adequate fixation time and adequate rinsing time.

PROBLEM : WET IMAGE

CAUSE: Dryer not working, old fixer or lack of replenishment.

ACTION : Check dryer temperature, last time fixer was changed

and change or replenish if necessary

PROBLEM : GRAY IMAGE

CAUSE: Contaminated solutions, old solutions, lack of replenishment

Improper washing after exposure to chemicals

ACTION : Check replenishment frequency, last time solutions

were replaced and change if necessary. Pour

fixer first and then developer. When replenishing use caution not

to contaminate developer with fixer

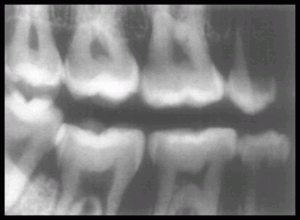

PROBLEM : OVERLAPPING LINES

CAUSE: Films were processed too close together, dirty rollers

ACTION : Check processing technique

FILM HANDLING AND STORAGE ERRORS :

Ideal film storage temperatures are between 50 and 70 and between 30 to 50% relative humidity.

Any increase is known to cause increased sensitization of the film emulsion

Extra oral films should be stored in a vertical orientation to prevent pressure artifacts.

Failure to maintain these cardinal rules in the radiographic unit leads to production of lightâ€, warped images and artifacts like.

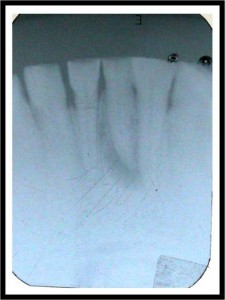

1.Tree like artifact — by static electricity (Dark tree like lines running across the film).

2. Smudge static – electricity produced by polyester clothing (Black smudges on the film).

3. Crescent or halfmoon – Fingernail (Dark cresent on film).

4. Finger print pattern – Dark finger prints on film.

PROBLEM : TREE-LIKE ARTIFACT

CAUSE: Static electricity, static from clothing or carpet

ACTION : Use antistatic solution in intensifying screens, install

humidifier in processing room if necessary, stand on antistatic

pad while processing, and open cassette slowly

PROBLEM : SMUDGE STATIC

CAUSE: Static electricity, static from clothing or carpet

ACTION : Use antistatic fabric softener when drying clothes

PROBLEM : CRESCENT OR HALF MOONS

CAUSE: Rough handling of film, fingernail pressure, bending or

creasing

ACTION : Handle film gently

PROBLEM : FINGERPRINT PATTERN

CAUSE: Moist hands, touching film before processing, finger

contaminated with developer

ACTION : Wash and dry hands before processing films, handle

Film by edges only.

PROBLEM: DEVELOPER CUT-OFF

CAUSE: straight white border appears due to low level of developer

solution and represents an underdeveloped portion of film,

ACTION: Check the developer level before processing films, make

certain that all films on the film rack are completely immersed

in the developer solution.

PROBLEM: FIXER CUT-OFF

CAUSE: Straight black border appears due to low level of fixer

solution

ACTION : check the fixer level before processing films, make

certain that all film rack are completely immersed in the fixer solution

CAUSE: white or dark areas appear on films when two films come

in contact with each other during manual or automatic

Processing. Films overlapped in developer have white areas, in

fixer have black areas.

ACTION: Ovoid overlapped films

PROBLEM: AIR BUBBLES

CAUSE: White spots appear on the film when air is trapped on the

Film surface after the film is placed in the processing solutions, air

bubbles prevent the chemicals from affecting the emulsion in that area

ACTION: Gently agitate and stir film racks after placing them in the

processing solutions.

PROBLEM : SCRATCHED FILM

CAUSE: White lines appear when the soft film emulsion is removed

from the film base by sharp objects

ACTION: Use care when placing a film rack in the processing

solutions, avoid contact with other film hangers, sharp objects.