X-RAY FILMS

Introduction

X-ray film is an image receptor.

It is a type of photographic film, in which an image is formed by

the exit radiation exposing the film.The film is composed of 2

principal components namely the base& emulsion.

Base:

0.2 mm thick & made up of clear, transparent cellulose acetate or

Cellulose nitrate.Cellulose acetate is used because it is less

inflammable. Recently polyesters [polyethylene teraphthalate] are

used.The base should be flexible for easy handling{manipulation}.

Emulsion:Consists of homogenous mixture of gelatin & silver

halide crystals.The gelatin is made from cattle bone.The gelatin is

clear so that it will transmit light & sufficiently porous to allow the

processing chemicals to penetrate it & reaches the silver halide crystals fast without affecting the strength.

Emulsion

Silver `halide crystals namely the Silver bromide& Silver iodide are embedded in

the gelatin matrix.

A protective coating of gelatin is added over the emulsion[super coat].

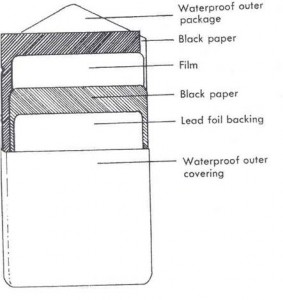

The film is encased in a protective black paper wrapper & backed by a thin sheet

of lead foil.Black paper covers the film & shields the film from light.

Lead foil protect the film from secondary or scattered radiation &gives rigidity of

the packet.The films are wrapped in packets of white, pebbled,moisture-resistant

paper or polyvinyl wrap.

There is a raised dot[Embossed dot]

is seen on one corner of the

film packet,which helps to orient

the film towards the x-ray beam.

Types of Xray Films

1.Direct exposure or non-screen films.[Intra-oral films].

2.Indirect exposure or screen films.[Extra-oral films in

combination with intensifying screens in a cassette].

Intra-Oral Films:

-Periapical films.

-Bite wing films.

-Occlusal films.

Processing The Xray Films

Radiographic film is the recording medium[ image receptor].The photons

chemically changes the photosensitive silver halide crystals in the film emulsion

These chemically altered crystals constitute the latent image [ invisible image].

Due to chemical action of the developing process the latent image is converted

into visible image.

Latent Image Formation : Silver halide crystals absorb X-radiation during

x-ray exposure & store the energy from radiation.

The stored energy within the silver halide crystals forms a pattern & creates an

invisible image with in the emulsion on the exposed film.This pattern of stored

energy on the exposed film can not be seen & is referred as latent image.

When the x-ray photons hit the surface of the film emulsion, some silver bromide

crystals are exposed & energised while others are not. The exposed silver

bromide crystals to x-ray photons are ionised & the silver& bromine atoms are

separated.

Collectively, the crystals with aggregates of silver at the latent image centers

become the latent image on the film.

Steps in Processing Xray Films

1. Developing the films.

2. Rinsing the films.

3. Fixing the films

4. Washing the films.

5. Drying the films.

Developer Solution: It reduces all silver ions in the exposed crystals of silver bromide to metallic silver.To get a diagnostic image, the reduction process must be restricted to crystals which contain latent image.Areas that have many exposed crystals will be more dense

[ black] because of their higher concentration of black metallic silver granules after development.

Components:

1]Developer– primary function is to amplify the latent image by converting the exposed

Silver halide crystals into metallic silver grains.

Elon& Hydroquinone are commonly used.Elon is also known as metol.

ELON [Monomethy-para-aminophenol sulphate]—acts quickly to bring out the gray shades in an image.

HYDROQUINONE[Para hydroxy benzene]—brings out the contrast of the image.

2]Preservative—Sodium sulphite which is an antioxidant is used.

A] It helps to protect the developer from being oxidized by atmospheric oxygen.

B] It helps to extend the useful life of the Hydroqunone & Elon.

3]Accelerator[Activator]:The alkali sodium carbonate is used.The

developing agents are active only in an alkaline {high pH} environment.

Activators help to soften the gelatin,so that the developer agents diffuse

more rapidly into the emulsion & reach the silver bromide crystals more

effectively.Sodium Hydroxide,Sodium metaborate & tetraborate are also used.

4]Restrainer:Potassium bromide is used.

It helps to control the developer & to prevent it from developing the

exposed and unexposed silver halide crystals.It is more effective in

depressing the reduction of unexposed crystals, there by acts as an antifog agent.

Developer replenisher:It is a solution made for topping off the developing solution each morning. It is a more concentrated solution of developer added to replace those depleted from the original solution,without increasing the volume.

Rinsing: The film is washed for 15-20 seconds before being placed in the fixer. This helps to remove the alkali activator.

Fixer Solution

Primary function of fixing solution is

1] To remove {dissolve} the undeveloped silver halide crystals from the emulsion.

2] To harden{fix} the film emulsion.

If the unexposed crystals are not removed , the image on the

radiograph is dark & nondiagnostic.

Presence of unexposed crystals causes film to be opaque.

Basic Ingredients:

1] Clearing agents-[Fixing agents].

2] Preservative.

3] Acidifier.

4] Hardener.

Fixing Agent

1]Clearing agent:The film emulsion has to be cleared by dissolving & removing the unexposed silver halide crystals.Sodium or Ammonium thiosulfate is commonly used. This chemical clears the film so that the black image produced by the developer becomes readily distinguished.

2]Preservative: Sodium sulfite is used.Action is to prevent chemical deterioration/ decomposition of the fixing agent.

3]Acidifier: Acetic acid or sulfuric acid is used.Function is to neutralize any contaminating alkali from the developing solution& to inhibit any carryover of the developing agents.Unexposed crystals may continue to develop in the fixing tank due to un-neutralized alkali & un-inhibited developing agents from the developing solution.

4]Hardener: It prevent damage to the gelatin by subsequent handling. Helps to shorten the drying time. The agents used are potassium alum. Aluminium potassium sulfate & chromium potassium sulfate are also used.

Washing: After fixing the film is washed in tap water for adequate time to assure removal of all processing chemicals.