A tooth burnisher is a hand held dental instrument that is used to make the filling of a tooth shinier. This can be done by polishing the restoration with a rubbing motion, as the word ‘burnish’ suggests. It is more commonly used to burnish amalgam fillings, but it can also be used to shape the composite or glass ionomer cement (GIC) filling before they set.

What are the types of tooth burnishers and their uses?

There are various types of burnishers, ad they are classified based on the shape of their end parts. They are:

- Flat plastic burnisher

- Ball burnisher

- Beavertail burnisher

- Acorn burnisher

- T-ball burnisher

- Rotary burnisher

In the dental arts there is a definite need for tools and methods to produce a smooth polished surface on exposed metal surfaces such as gold dental castings utilized to restore lost tooth structure. At present these smooth polished surfaces are produced with abrasives which are rubbed and worked against the gold surface with a tool. The typical prior art procedure for polishing gold comprises several steps. Irregular surfaces on the rough casting are ground off with a coarse abrasive wheel. Surfaces on the top of the casting (occusal) are then ground into good matching shapes or good occlusion. Deeper parts are accented with steel or carbide burs and mounted stones. This leaves a shiny surface which is scratched and cut and therefore not too desirable. Next, the surfaces are semi-finished with an abrasive material contained in rubber. This is applied with a rubber wheel. Finally, a cloth wheel is used to produce a high shine by polishing with tripoli and gold rouge.

The problem with this approach is that the abrasive usually cannot be properly worked to smooth out the cut and scratched surface. The rubber points and wheels which are used in dental handpieces are totally inadequate to reach the small tight areas which have been accentuated or scored by the steel and carbide burs and mounted stones. The result is that the higher surfaces tend to be ground away without achieving progress toward polishing the deep areas. Thus, the good occlusion can be destroyed without really accomplishing an adequate polish. In fact, in the prior art this has constituted such a problem that the polishing process may consume 90 percent of the time required to finish and polish a crown or bridge gold restoration.

The rotary dental burnisher contains a shank portion that tapers down and connects to a fluted burnishing head. The rotary burnishing head are polished, rounded, and elongated, and has ridges on the surface. It has been found that a burnisher produces the desired polished finish in one or two minutes without removing any gold from the restoration. In this way, deep occlusal anatomy can be established to an extent heretofore impossible. A polish far superior than the prior art results and the good occlusion established in the rough finishing is not destroyed. No cutting edges are present and no abrasives are required. Instead the tool operates by a slight hammering and friction process which smoothens the surface.

The T-ball burnisher has a T-shape at its working end, and one of the ends of the T-shape is shaped like a ball. The ball-end dental burnisher is usually used as a probe to find specific orodontal margins

What are the parts of a tooth burnisher?

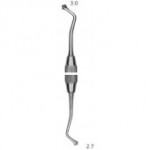

The tooth burnisher can be divided into three parts: the working ends, the shank, and the handle. The working end is at the very end of the tooth burnisher, and the shank will connect the working end to the handle.

The working ends of the burnishers are angled to allow the operator to reach the posterior tooth at the back of the mouth more easily. This is because the area at the back of the mouth is smaller and narrower compared to the anterior area of the mouth. If the working ends are not angled, it is quite hard and imporssible for the operator to reach certain areas.

Either or both ends are rounded and smooth for the tooth burnisher to carry out its function perfectly. If the ends are rough, they would produce a rough surface instead of a smooth one. A rough restoration surface can trap plaque biofilm, and promote teeth decay instead of preventing it.

The ends can be single-ended or double-ended in structure. In double ended structure, one end will be used to burnish the mesial side of the restoration (the side nearer to the center of the mouth), and the other end will be used to burnish the distal end (the direction towards the posterior part of the mouth).

Burnishers are precision dental hand instruments and these delicate instruments need careful handling and maintenance to preserve their quality and promote longer life of the instrument. Dental burnishers are multipurpose precision hand instruments and are also used in the operative procedures of eye, ear, nose, and throat. As they are made out of stainless steel mainly, they can be autoclaved and reused. Some handles are coated with a layer of silicone for soft and firm grip, so that slipping of the instrument can be prevented. Each manufacturer would have provide a manual along with the instrument to describe the proper way of sterilizing the instrument, and should be followed accordingly.