These restoration are made up of metal alloys or porcelain.

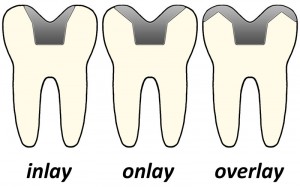

Eg: Cast restoration are

Full crowns

Onlays

Inlays

Pinlays

Definition:

Restoration which is constructed out of the mouth from materials like gold alloys, composite and porcelain and then cemented back into the prepared cavity of the teeth.

HISTORY AND INTRODUCTION:

Classification:

Metallic inlays

Non metallic inlays

Metallic Inlays:

Made of gold alloys

Made of Nickel chromium alloys

Non Metallic Inlays:

Made of porcelain

Made of composite

Intra coronal restorations

Inlays, Onlays, Pinlays

Extra coronal restorations

Full crowns, Partial veneer crown

STEPS IN INLAYS:

1.Cavity preparation

Bevel

Divergence Occlusally

2. Wax Pattern:

Directly into oral cavity

Indirectly on the cast by inlay wax

3. Sprue:

Spruing and attaching it to the crucible former

4. Investing

5. Dewaxing or burn out

6. Casting procedure: by which molten alloy is forced by centrifugal pressure

7. Cleaning and finishing of inlay

8. Cementation of inlay

For preparation of indirect wax pattern impression has to be taken for preparation of die. Before taking impression we have to see the conditions of gingiva which is called as gingival tissue management:

Advantages OF INLAY:

1.Excellent strength

Very good strength in thin section

These alloys have certain amount of ductility

Very good marginal adaptation

2. Indestructable in oral fluids (therefore nobility of gold)

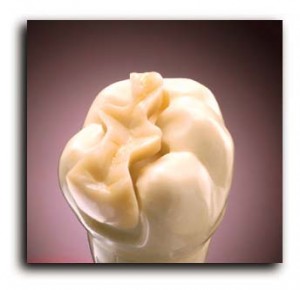

3. Capable of reproducing precise form and minute details of cavity and occlusal morphology

4. Relatively unaffected by tarnish and corrosion

5. No molecular or dimensional changes once casting is completed . In case of amalgam molecular changes are seen even after the final setting.

6. Restoration can be finished/ polished extra orally (these procedures create heat and since this is done in the cast, It is not detrimental to pulp)

7. Can be used to solve periodontal problems (to get proper contact point, contoured embrasure (good marginal ridge)

8. Maintains anatomic form even under functional stress

9. It is very versatile material so that we can do any amount of manipulation. Soldering of restoration can be done even after polishing.

10. It is abrasion resistant

DISADVANTAGES OF INLAY:

1.Lack of close adaptability to cavity walls

2.Requires two or more sittings

3.There is space of 10-160um is always present. So this is sufficient to cause cement to dissolve. This leads to secondary caries.

4.Esthetics. It has inharmonious colour

5.Thermal conductivity

6.Galvanism

7.May cause abrasion of opposing tooth structure

8.More expensive (material + lab charges)

9.Time consuming for both doctor and patient and requires skill of operator

10.Need of temporary dressing

INDICATIONS FOR INLAY:

1. Extensive involvement of tooth structure. This restoration reinforce the tooth structure.

Large carious lesions where stress bearing areas are involved.

Large lesions associated with secondary caries involvement around restoration

Cusp fracture, fracture of marginal ridge

2. In patients who are relatively immune to caries

3. To improve the periodontal problems (In case of splinting and there is no over changing in cast gold restoration)

4. In case tooth has to act as retainer for RPD / FPD

5. To restore ideal occlusion

6. In cavities with sub gingival margins.

7. To prevent galvanism

8. Multiple castings: Inlays are indicated when numerous other castings have been placed.

9. Esthetically better compared to Ag-Hg

10. In RC Treated teeth (Controversial)

CONTRAINDICATIONS:

1.Very young patient

a – Large pulp chamber

b – More susceptible to D.C

c – Can’t bear the work done for preparation

2. Very old patients – poor periodontal conditions.

3. High plaque index / high caries index

4. Esthetic demands of patient

5. Dissimilar metals

6. Patient with poor oral hygiene

Nobel Metals used for inlays:

These gold alloys classified as

Type I to type IV by function

Type I (Soft) – small inlays easily burnished subjected to very light stress

Type II (Moderate): Inlays subjected to moderate stress. Thick ¾ crowns, Abutments and partial and full crowns.

Type III (hard) :

Inlays subjected to high stress ¾ crowns, thin cast backings, full crown denture bases, short span fixed partial dentures.

Type IV: (Extra hard)

Inlays subjected to very high stress, Denture bases, bars and clasps partial denture frame work and long span FPDs

FABRICATION OF WAX PATTERN:

Two methods:

Direct method:

Where wax pattern is done on the prepared cavity of tooth structure.

Indirect method:

Where wax pattern is done on the cast

ADA Sp. No. 4 for inlay wax

Type I: medium wax is used for direct pattern where melting point is high.

Type II: Soft wax is sed for indirect pattern where melting point is low

Composition of inlay wax:

Paraffin wax: – 40 to 60%

It is mineral source of wax obtained during distallation of crude petroleum. It flakes when trimmed and it does not present smooth surface and glassy surface. So other waxes and natural resins are added as modifiers.

Carnuba wax: is a vegetable source of wax occurs as fine powder on the leaves of certain tropical palms. It has a high melting point. It is combined with paraffin wax to reduce flow at mouth temperature. It also gives glossiness to the pattern.

I think that’s a great tips and methods for restoration of teeth.So thanks for the information.